Building a new product that relies on computer vision and artificial intelligence can be a challenging and time-consuming process because these are sectors that are continually expanding and in high demand. Researching and testing algorithms, building and refining neural networks, and finally fusing the resulting software with hardware components are all steps in the development process that are often included. Each level calls for specific expertise, as well as tools and materials that might not be easily accessible. Additionally, it can be challenging to keep up with the most recent advancements and guarantee that the product maintains its competitiveness as technology advances, something usually referred as a “tech dept”.

On a recent blog post we have discussed about minimizing Vision AI development time. Minimizing cost and risk is essential whether it is a proof of concept or a minimum viable product for the industrial, manufacturing, logistics, smart spaces, smart retail, or other sectors. This frequently entails coming up with novel solutions to straightforward issues, such lowering the volume of data needed for training, tailoring algorithms to certain use cases, or utilizing already-developed software components. To make sure that the product fits their wants and expectations, it could also be required to communicate with potential customers and do comprehensive market research. Businesses can increase their chances of success in these quickly developing industries by approaching product development methodically and strategically.

Each business case is unique in various ways, from cost limitations, accuracy requirements, to specific visual, product & environmental conditions, or integration with existing tech stack & processes.

The first step in developing a new Vision AI solution is properly formulating the problem – working on the Digital Vision Twin as we prefer to call it. It allows you to gather user requirements, formulate the problem and propose a solution to the problem.

With Digital Vision Twin, you can streamline the process of developing Vision AI solutions and ensure that you are addressing the key issues in a systematic and effective way.

The main purpose of any end-to-end Vision AI platform is to address this very challenge; ecosystem fragmentation. It is crucial to provide a full software & orchestration infrastructure, that brings together all the Building Blocks necessary for deploying & scaling Vision AI sensors & solutions.

The platform becomes a central hub providing an easy-to-use interface that enables you to stay on top of your Vision AI operations.

A recent research from McKinsey & Company revealed that 74% of respondents failed to scale Vision AI; deployments were stuck to prototype phase. According to Deloitte Survey on AI Adoption, 91% of AI projects fail to meet expectations:

- Obstacles from existing experience and organizational structure;

- Infrastructure limitations;

- Data collection and quality;

- Lack of engineering experience;

- Excessively large scale and complexity;

The full software & orchestration infrastructure provided by Computer Vision AI Platforms is necessary to deploy either 2 or 2000 devices.

Building a new product that relies on computer vision and AI can be a complex and time-consuming process, making time-to-market crucial for gaining a competitive advantage. Utilizing well-defined and streamlined product development processes, access to the latest technology, and skilled professionals with expertise in computer vision AI can expedite the development process. End-to-end computer vision platforms help speed up the time-to-market by providing a collaborative environment for efficient data collection and management, streamlined sensor deployment, and scalable algorithm development.

The Importance of Minimizing Cost and Risk

Costs and uncertainties must be considered when developing a new product. While lowering risk assures that the product is viable and long-lasting in the market, minimizing cost guarantees that the product remains lucrative. Carefully selecting the product’s materials and manufacturing procedures is one approach to save expenses. This may entail evaluating the costs and benefits of many solutions and choosing the most suitable ones. Reducing waste and streamlining the supply chain are further ways to cut costs. To ensure that supplies and goods are delivered on schedule and with the least amount of waste possible, this may need strong collaboration with suppliers and logistical partners especially taking into account that the global semiconductor shortages are not ending yet. Before introducing the product, it is crucial to deploy a P.O.C. (aka Proof of Concept or Pilot) in order to make sure that all software and hardware components meet the requirements and that the solution is behaving as expected.. Surveys and focus groups may be used in this process to obtain opinions and pinpoint potential areas for improvement. Before putting the product on the market, it may also be advantageous to test it in a controlled setting to find and fix any problems or defects. A new product can be prepared for market success by taking these steps to reduce costs and risks.

McKinsey & Company

According to a research from McKinsey & Company, in 2020 the 74% of respondents claimed that they have not yet successfully scaled Industry 4.0 successfully. This means that they have been stuck in the pilot phase for various reasons.

In the industrial sector, computer vision is used for quality control, predictive maintenance, and process automation. For example, a new vision AI sensor that can detect faults in industrial machinery and predict maintenance requirements can significantly reduce downtime and costs, while also improving product quality.

Computer vision is used in production for component inspection, assembly verification, and defect detection. The expense of product recalls and rework can be decreased with the aid of a new computer vision technology that can automatically identify flaws in manufactured goods, assuring high quality standards.

In logistics, computer vision is used for package tracking, inventory management, and shipment verification. A new computer vision solution that can accurately track and verify shipments can help reduce costs associated with lost or misplaced packages.

Security, traffic monitoring, and energy control in smart spaces all use computer vision. High energy expenditures may be decreased with the use of a new computer vision solution that can monitor and optimize energy usage in buildings.

Computer vision is utilized in smart retail for loss prevention, inventory management, and customer analytics. Costs related to overstocking and understocking can be decreased with the use of a new computer vision technology that can assess consumer behavior and enhance inventory management.

End-to-End Platforms for Computer Vision and AI Product Development

End-to-end platforms for computer vision and AI product development, like PerCV.ai, can reduce cost and risk by offering a collaborative environment that enables quick prototyping and deployment of numerous sensors and devices, effective data collection and management, simplified sensor deployment and management, and scalable algorithm development.

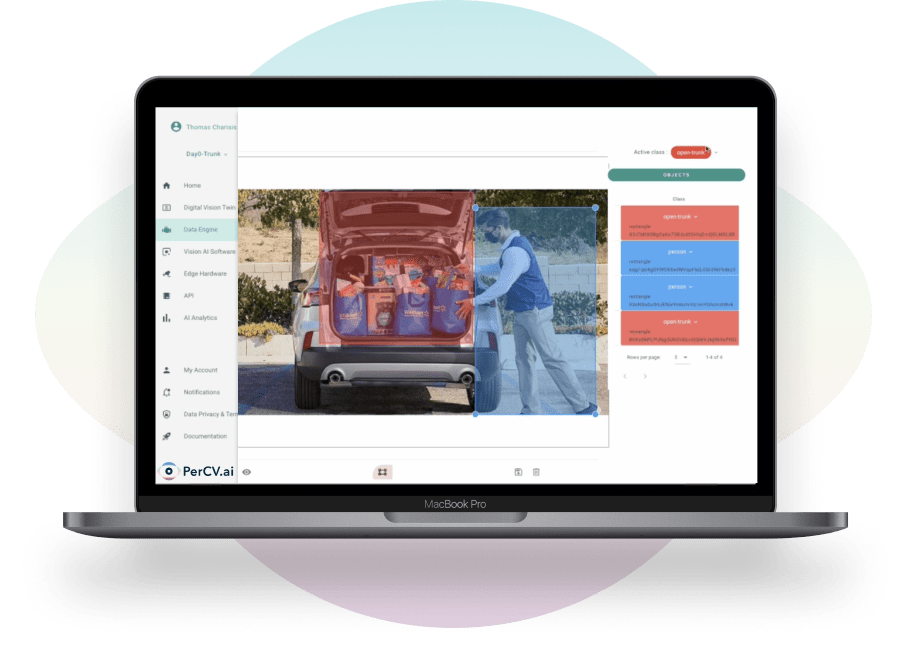

From ideation to prototyping to product development, PerCV.ai offers end-to-end product development assistance. Users can start by defining the issue and turning their needs into a proposal that has been verified in a digital environment. After that, they can begin gathering data to verify their hypotheses by using either already-existing data or PerCV.ai edge devices. Data collected can be curated, annotated, and augmented within the data engine, which ensures that there are enough data to train the model and measure its performance.

Users can fit one or more models to the data and evaluate their performance once they have some sample data. PerCV.ai eliminates all the complexity involved in setting up the infrastructure needed to train models while also giving users the scalability they need to execute several trials. By using the cloud inference API or by directly deploying to a device by downloading a container or a binary application file, testing the model is relatively simple. Users have the option of training one or more segmentation, classification, and detection models. Users can also choose a model that will fit on the desired HW.

Users can now begin deploying sensors to evaluate their application in actual environments. Although Irida Labs can provide sensors, users can link any device as a sensor by using the percv.ai edge device SDK. (python). Users can choose a device and install a new model after it has been trained, making A/B testing, model comparison, and user experience simple. Therefore, integrating any device and deploying a learned model on it should be simple for a user.

Building a new product relying on computer vision and AI requires minimizing cost and risk. End-to-end platforms for computer vision and AI product development, like PerCV.ai, can reduce cost and risk by offering a collaborative environment that enables quick prototyping and deployment of numerous sensors and devices, effective data collection and management, simplified sensor deployment and management, and scalable algorithm development. Companies can use such a platform to maintain cost and risk management while gaining a sizable competitive advantage in these quickly expanding industries.

End-to-end Software & Services Platform

To Deploy Computer Vision & AI at Scale