The Vision AI Solution for Packaging Integrity & QA is a robust, Vision AI-based, in-line packaging integrity & quality assurance system powered by PerCV.ai, that eliminates the need for human inspection in production lines.

It allows 24/7, unsupervised monitoring of products traveling on manufacturing production lines, detecting:

Surface quality of bags (tears, dents, spills, underweight, dirty)

Accuracy in defects & printing failures

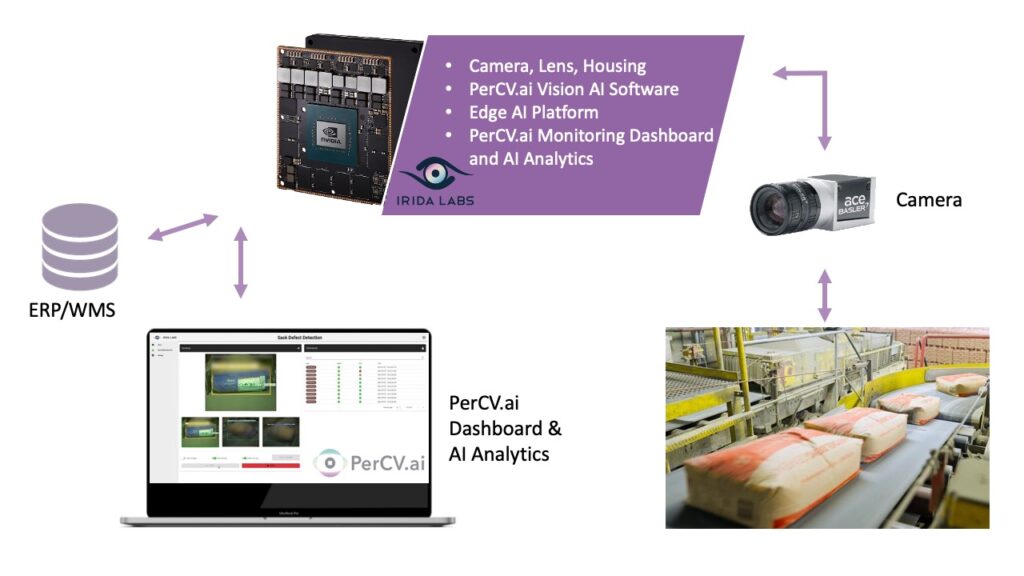

Vision AI Solution Components

Fully custom Vision AI software, tailored to each plant production specifics. Under the hood, PerCV.ai platform for on-device Vision Intelligence is utilized to build efficient and robust Defect Detection, Packaging Integrity and Quality Assurance solutions, that run in real-time and rely solely on our proprietary ML engine.

Host Device: e.g. Edge Device or Industrial PC

AI Accelerator: ADLINK NVIDIA® Jetson Nano™ Edge Inference Platform provide the sensor with the computational power required to run advanced AI vision workloads

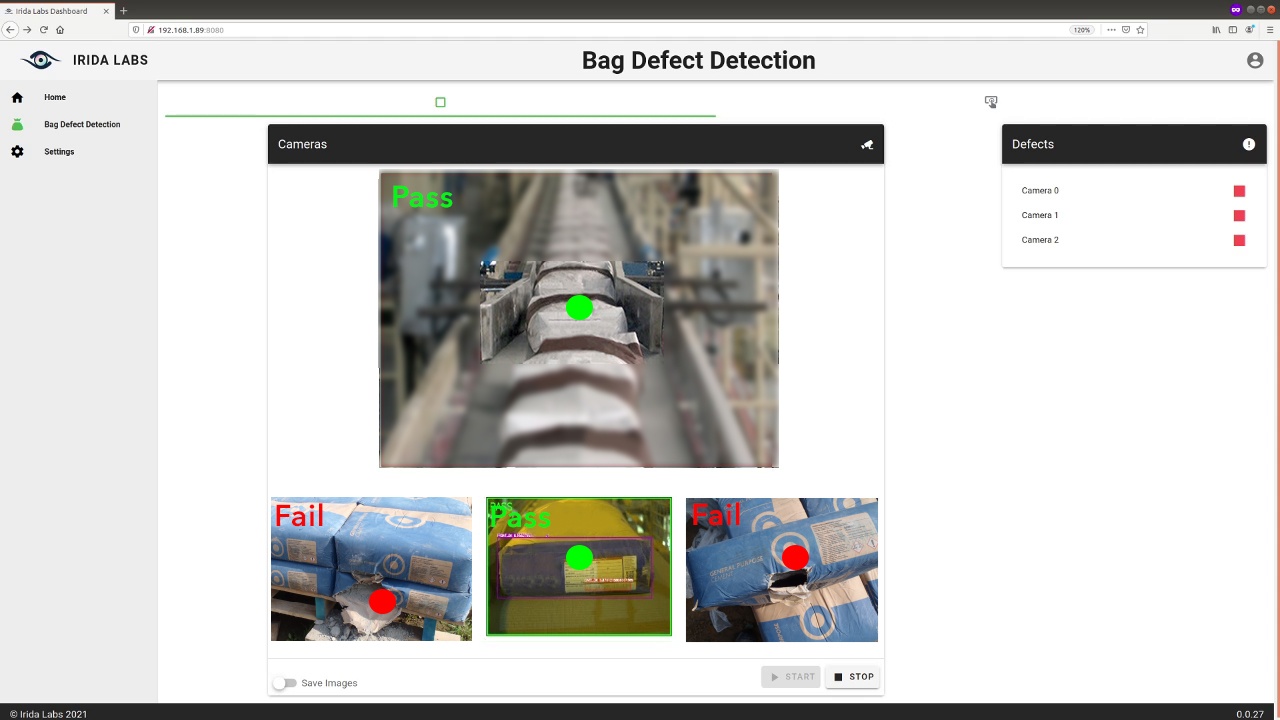

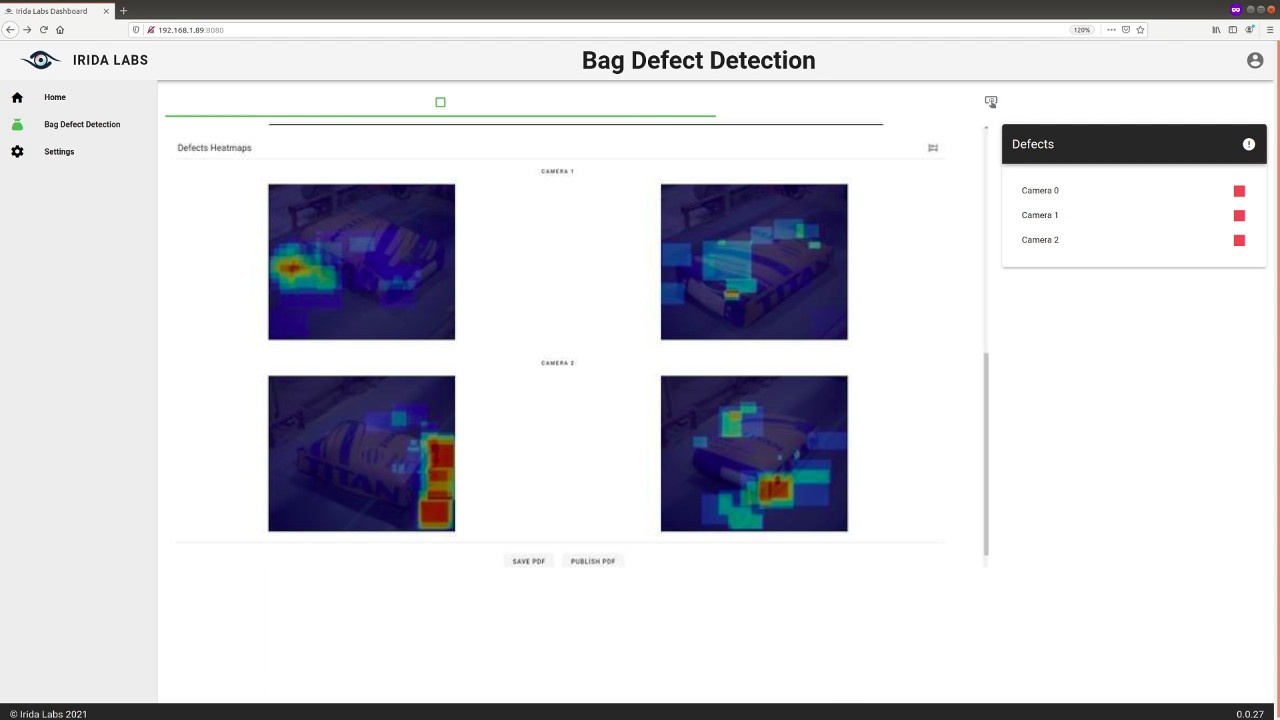

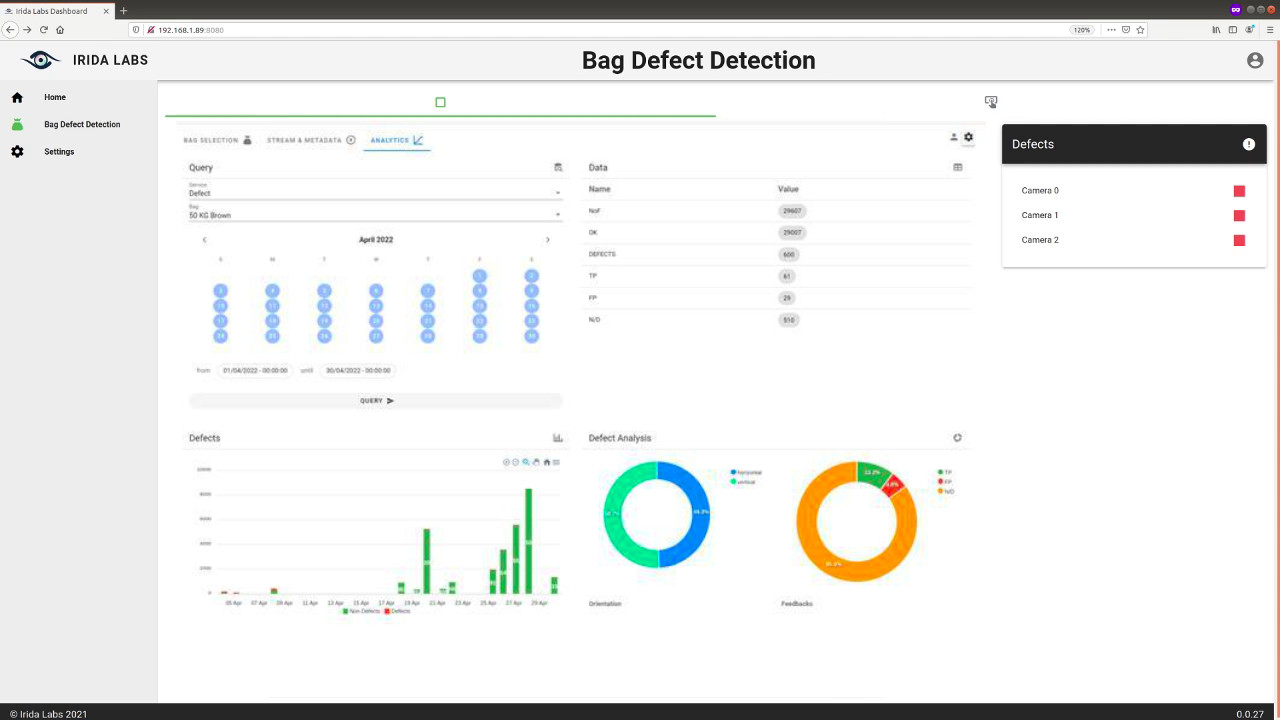

The PerCV.ai Dashboard & AI Analytics is providing real-time, visual check of the functionality of the system.

- Automatic, concurrent image capturing based on camera triggering mechanism

- Capture data / images during system operation and store to the local Industrial PC

- Visually check the Defect (or Production Date) that the AI system detected in real-time

- Data analytics and graph-based statistics (plots)

All metadata can be easily transmitted to your existing software stack (i.e. ERP, WMS etc) via the industry standard MQTT & API protocol

Basler ace camera and lens

Camera module and optics are protected from the industrial environmental conditions (vibrations, dust, moisture) with a compact IP66/IP67 camera enclosure

- Robust construction, compact size

- High IP protection glass

- High chemical resistance

- Vibration-proof mounting

- Excellent heat dissipation

Get in Touch with our Team!

Get in touch in order to explore further how our Vision AI Solution for Packaging Integrity & QA, powered by PerCV.ai, can help automate the integrity inspection and quality assurance procedures at your company. We would love you to give us a very brief description of your implementation scenario, so that we assemble the most qualified team of Vision AI experts for our discussions!

Benefits

QA practices in manufacturing have long relied on visual inspection of products rolling off the production line. However, the error-prone nature of human inspection not only is labor-intense, but also suffers from optical illusions and fatigue.

24/7 Automated Quality Inspection

Labor cost reduction Product Consistency Real-time monitoring from anywhere in the plant

VISION AI at the EDGE

Fully custom Vision AI software, tailored to the plant production specifics

Edge device processing - No cloud

Our Vision AI technology surpasses human vision in quality and quantity measurements because of its speed, accuracy, and repeatability. Combined with the necessary optics, Vision AI can also detect defects that are impossible to consistently spot with the naked eye!

Zero-Defect Palletizing

Reduced Cost of Poor Quality (COPQ) Compliance with regulations (label/date misprint) Reduced regulatory fines risk

Production Improvement

Identify production weaknesses & inconsistencies

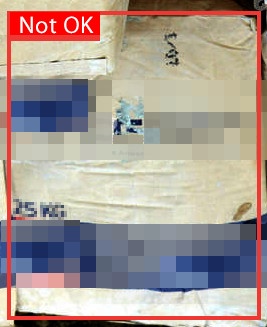

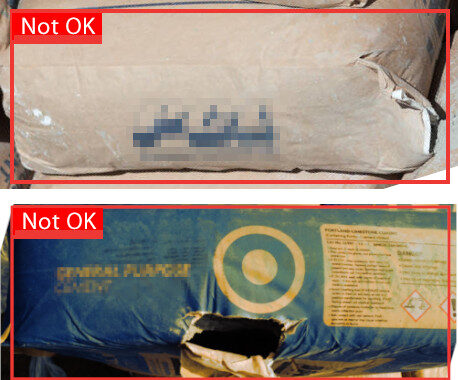

Cement Bag Defect Examples

Defect: Product Spill

Defect: Printing Failure

Defect: Cut or Damaged Edge

Success Story

Collaborating with Barler AG, we successfully deployed a Vision AI Packaging Integrity & QA solution that replaces manual inspection work at a leading Cement Industry production line. With the help of AI Computer Vision, cement factories are able to reduce their defects, improve their efficiency, and reduce labor costs.

Industry Brief

In this Cement Industry Brief we present how Irida Labs’ PerCV.ai platform for on-device Vision Intelligence is utilized to build efficient, robust and scalable Industry 4.0 solutions for Cement Bags Identification & QA in conveyor belt systems that run in real time and rely solely on our proprietary ML engine.

Vision AI - one step closer to human-like intelligence

PerCV.ai, Irida Labs’ end-to-end AI software and services platform, enables the real-time identification and QA of multiple products in indoor or outdoor conveyer systems, such as cement bags of all types. It can be easily deployed on pre-existing production lines, allowing quick implementation at scale – moving from prototype to full-scale deployment in weeks, not years. With pre-trained AI/ML models and minimal data campaign requirements, the system can be quickly trained on identifying new products (i.e. bag sizes, product types, new packaging) with remarkable accuracy & consistency.

Custom Implementation?

Do you need a custom solution, tailored to your specific use case? Talk to our team, we will support you throughout the design and the deployment phases!