Industry 4.0

Autonomous Factories & Logistics with Computer Vision AI Solutions

Introduce Next Gen Industrial Automation

Boost efficiency, ensure quality, and enhance safety with Vision AI-powered industrial automation. From real-time quality control to warehouse monitoring and PPE detection, PerCV.ai Industry 4.0 Suite helps you cut costs and optimize operations.

PerCV.ai Industry 4.0 Suite

Personnel Safety PPE Monitoring

People Presence Detection

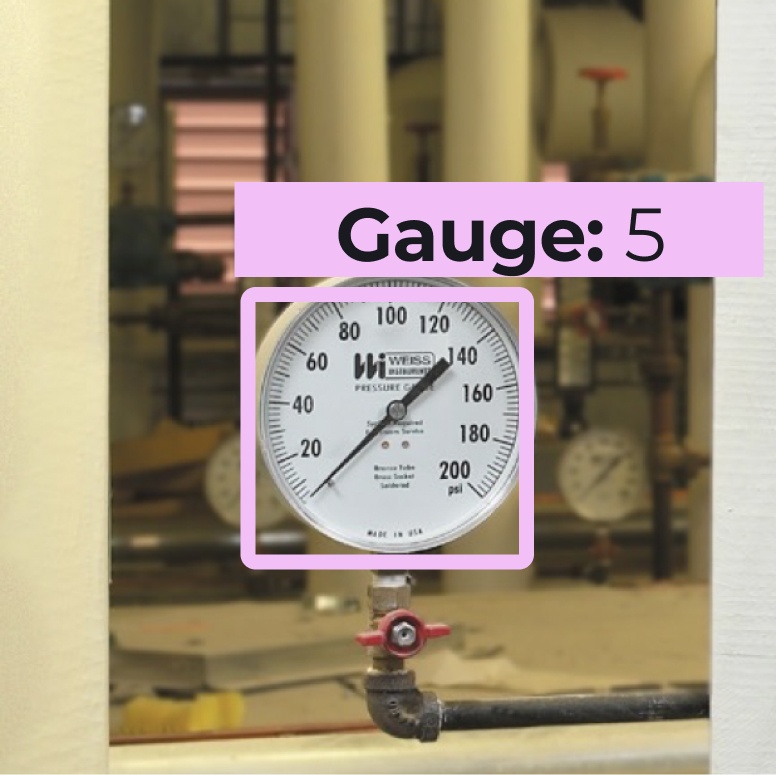

Analogue Gauge Digitization

Custom Vision AI

Designed Around Your Requirements

Vision AI Deployment Options

Vision AI Sensor

A ready-to-deploy hardware solution that integrates vision AI capabilities for real-time analysis and decision-making at the sensor level

Edge Solution

A powerful deployment option where vision AI models run locally on edge devices, ensuring faster processing, reduced latency, and enhanced privacy without relying on the cloud

Vision AI Camera

A camera with embedded vision AI accelerator, enabling direct image and video analysis to deliver actionable insights in real time

Vision AI: Industry 4.0 Digitization Catalyst

Digital Transformation Adoption

Sustainability & Environmental Policies

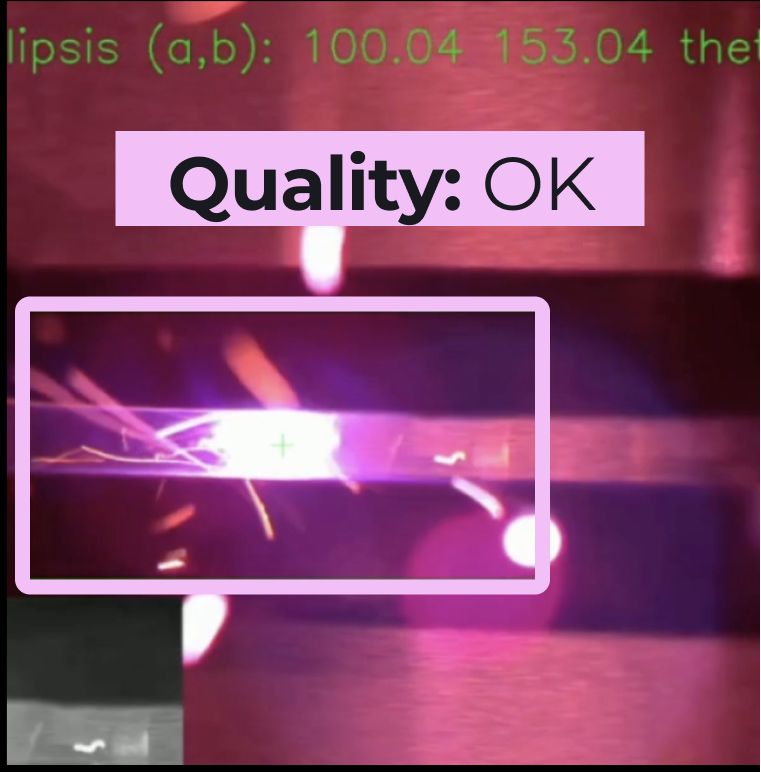

Quality Management

Health & Safety

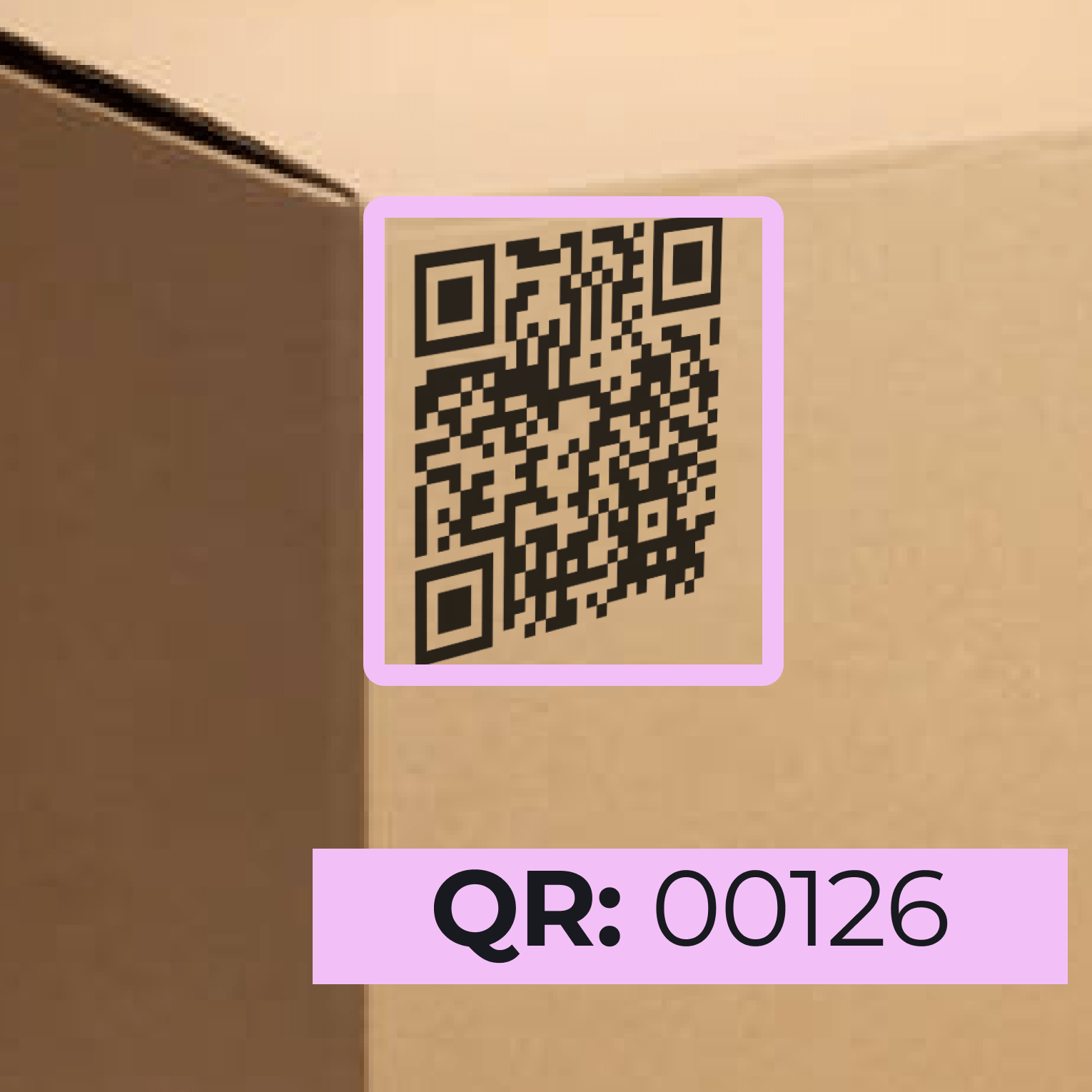

Supply Chain Optimisation

Regulatory Compliance

Smart Factory Success Stories

The solution significantly reduces the number of defective sacks being palletized, with accompanying reductions in labour costs. As a consequence, customer complaints about defective sacks have significantly decreased.

Learn More About Computer Vision Industrial Applications

USE CASE

A handful of real-world PerCV.ai Industry 4.0 implementations, complemented by the opportunities and the challenges stemming from our 10-year hands-on experience

DEMO

Watch this demo to see how Vision AI and edge computing enhance supply chain management by enabling real-time tracking, smart automation, and seamless system integration for Industry 4.0 applications.

BLOG

Discover how Vision AI and edge computing transform supply chain management with real-time tracking, automation, and seamless Industry 4.0 integration.