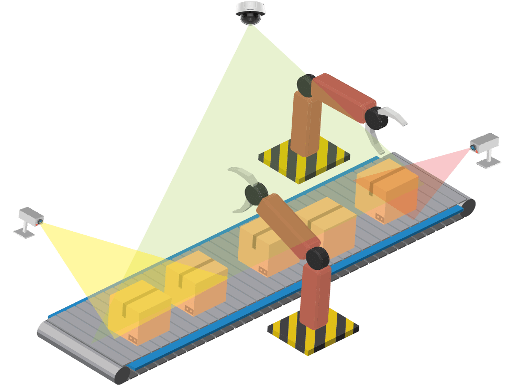

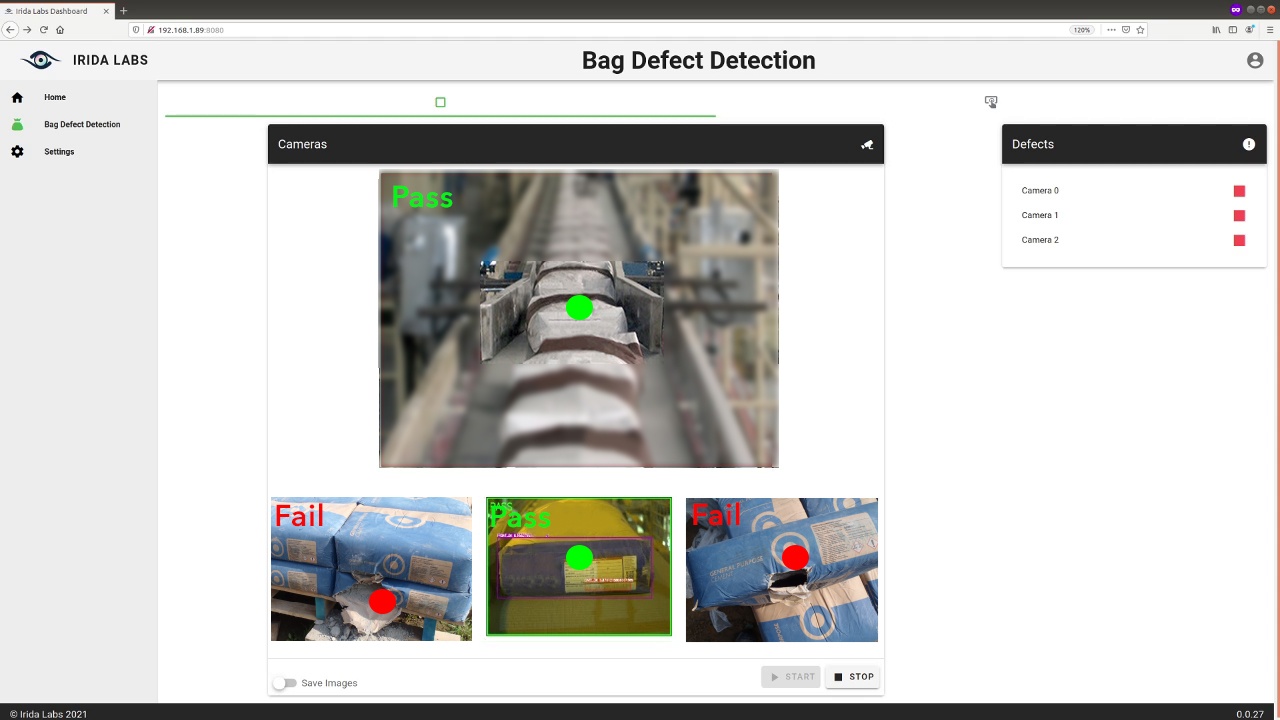

PerCV.ai, Irida Labs’ end-to-end AI software and services platform, enables the real-time identification and QA of multiple products in indoor or outdoor conveyer systems, such as cement bags of all types. It can be easily deployed on pre-existing production lines, allowing quick implementation at scale – moving from prototype to full-scale deployment in weeks, not years. With pre-trained AI/ML models and minimal data campaign requirements, the system can be quickly trained on identifying new products (i.e. bag sizes, product types, new packaging) with > 98% AP Accuracy.

Vision AI for Industry 4.0: A cross-field, holistic, edge-AI approach that can transform bounding boxes to real-world systems:

Vision AI offers a wide variety of applications for the Cement Industry, ranging from raw material – inventory management, quality inspection in production lines, real time operations monitoring to personnel protection & process safety. In this particular industry brief we focus on in-line monitoring and quality inspection on conveyor belt systems, with events tracking capabilities that provide real-time alerts about incidents that require immediate attention/action, such as occupancy limits violations, spill overs, operator safety at risk. Additional functionalities include high-level operations analytics, such as product flow, heatmaps and occupancy statistics for indoor & outdoor areas and zones of interest.

In this Cement Industry Brief we present how Irida Labs’ PerCV.ai platform for on-device Vision Intelligence is utilized to build efficient, robust and scalable Industry 4.0 solutions for Cement Bags Identification & QA in conveyor belt systems, that employ computer vision and AI at the edge, run in real time and rely solely on our proprietary ML engine.

Empowering Smart Manufacturing and Enhanced Decision-making

laser cutting, laser welding, additive process monitoring, quality inspection

| Cookie | Duration | Description |

|---|---|---|

| __cf_bm | 30 minutes | This cookie, set by Cloudflare, is used to support Cloudflare Bot Management. |

| bcookie | 1 year | LinkedIn sets this cookie from LinkedIn share buttons and ad tags to recognize browser ID. |

| bscookie | 1 year | LinkedIn sets this cookie to store performed actions on the website. |

| lang | session | LinkedIn sets this cookie to remember a user's language setting. |

| li_gc | 5 months 27 days | Linkedin set this cookie for storing visitor's consent regarding using cookies for non-essential purposes. |

| lidc | 1 day | LinkedIn sets the lidc cookie to facilitate data center selection. |

| UserMatchHistory | 1 month | LinkedIn sets this cookie for LinkedIn Ads ID syncing. |

| Cookie | Duration | Description |

|---|---|---|

| SRM_B | 1 year 24 days | Used by Microsoft Advertising as a unique ID for visitors. |

| Cookie | Duration | Description |

|---|---|---|

| _clck | 1 year | Microsoft Clarity sets this cookie to retain the browser's Clarity User ID and settings exclusive to that website. This guarantees that actions taken during subsequent visits to the same website will be linked to the same user ID. |

| _clsk | 1 day | Microsoft Clarity sets this cookie to store and consolidate a user's pageviews into a single session recording. |

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _ga_W6E27R14NE | 2 years | This cookie is installed by Google Analytics. |

| _gat_UA-156119957-1 | 1 minute | A variation of the _gat cookie set by Google Analytics and Google Tag Manager to allow website owners to track visitor behaviour and measure site performance. The pattern element in the name contains the unique identity number of the account or website it relates to. |

| _gcl_au | 3 months | Provided by Google Tag Manager to experiment advertisement efficiency of websites using their services. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| AnalyticsSyncHistory | 1 month | Linkedin set this cookie to store information about the time a sync took place with the lms_analytics cookie. |

| attribution_user_id | 1 year | This cookie is set by Typeform for usage statistics and is used in context with the website's pop-up questionnaires and messengering. |

| CLID | 1 year | Microsoft Clarity set this cookie to store information about how visitors interact with the website. The cookie helps to provide an analysis report. The data collection includes the number of visitors, where they visit the website, and the pages visited. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

| nQ_cookieId | 1 year | Albacross sets this cookie to help identify companies for better lead generation and more effective ad targeting. |

| undefined | never | Wistia sets this cookie to collect data on visitor interaction with the website's video-content, to make the website's video-content more relevant for the visitor. |

| Cookie | Duration | Description |

|---|---|---|

| ANONCHK | 10 minutes | The ANONCHK cookie, set by Bing, is used to store a user's session ID and also verify the clicks from ads on the Bing search engine. The cookie helps in reporting and personalization as well. |

| MUID | 1 year 24 days | Bing sets this cookie to recognize unique web browsers visiting Microsoft sites. This cookie is used for advertising, site analytics, and other operations. |

| test_cookie | 15 minutes | The test_cookie is set by doubleclick.net and is used to determine if the user's browser supports cookies. |

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt.innertube::nextId | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

| Cookie | Duration | Description |

|---|---|---|

| _bc_uuid | 10 years 3 months 16 days 18 hours | No description available. |

| AWSALBTG | 7 days | No description available. |

| AWSALBTGCORS | 7 days | No description available. |

| debug | never | No description available. |

| DEVICE_INFO | 5 months 27 days | No description |

| ln_or | 1 day | No description |

| loglevel | never | No description available. |

| nQ_userVisitId | 30 minutes | No description available. |

| prism_610420756 | 1 month | No description |

| rl_anonymous_id | never | No description available. |

| rl_user_id | never | No description available. |

| session_referrer | 30 minutes | No description |

| SM | session | No description available. |

| tf_respondent_cc | 6 months | No description |