At Irida Labs, we’re committed to pushing the boundaries of Edge Vision AI to solve real-world challenges in manufacturing. Today, we’re proud to share how our collaboration with AI-MATTERS and the Laboratory for Manufacturing Systems and Automation (LMS) is helping us revolutionize quality assessment in welding metal processes.

The Challenge

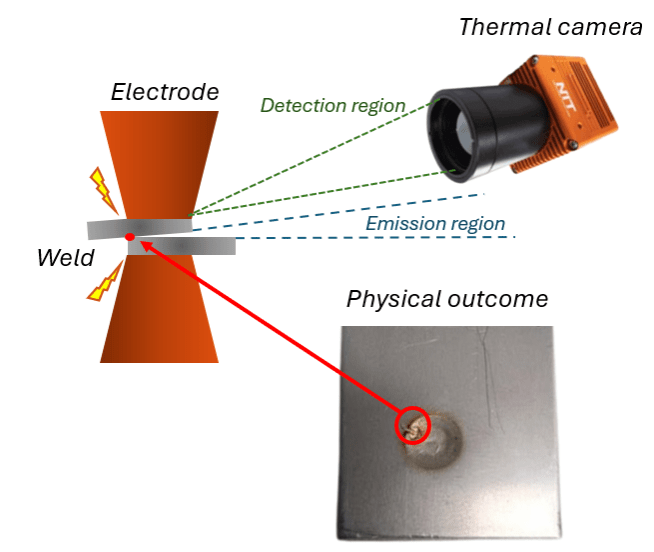

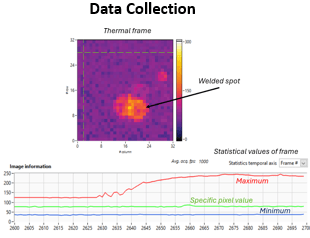

To meet rising production demands and improve quality assurance, we set out to test a data-driven solution using vision AI models for defect detection in welding processes. However, access to specialized equipment and manufacturing expertise was essential to move forward.

The Solution

Through AI-MATTERS, we gained access to advanced testing facilities, technical guidance, and a realistic test environment—enabling us to validate and refine our AI-powered solutions.

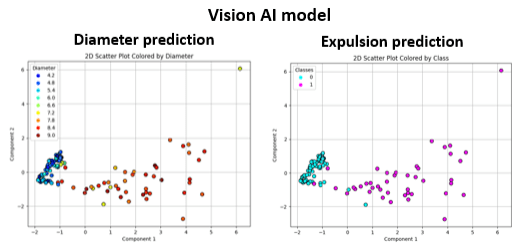

The Results

- High-speed prediction of expulsion defects and diameters in under 2 seconds

- Approximately 10% cost savings in robotic automation

- Over 97% accuracy in defect identification

- Upskilling of 10 team members in AI-based manufacturing technologies

“The results we’ve achieved with AI-MATTERS exceeded our expectations. It’s not just about the technology—it’s about transforming our entire approach to manufacturing,” says Christos Theocharatos, COO of Irida Labs.

This collaboration marks a pivotal step in our AI adoption journey. We’re now exploring ways to scale these solutions across additional QA processes and expand into logistics and supply chain optimization.

Is your organization ready to embrace the future of manufacturing?

Discover how AI-MATTERS can support your journey toward smarter, more efficient operations.