Industry 4.0: The Era of Smart Manufacturing and Digital Transformation

The fourth industrial revolution, Industry 4.0, has ushered in a new era of smart manufacturing and digital transformation. Industry 4.0 has transformed manufacturing by integrating advanced technologies such as artificial intelligence, the Internet of Things (IoT), big data analytics, and automation. It has given rise to the smart factory concept, in which interconnected systems and machines communicate and collaborate in real-time. In an increasingly globalized and technologically driven world, this paradigm shift is enabling manufacturers to achieve unprecedented levels of efficiency, productivity, and flexibility while also opening up new opportunities for innovation and competitive advantage. In this article, we will look at how computer vision AI is being used in Industry 4.0 and how it is shaping the future of manufacturing.

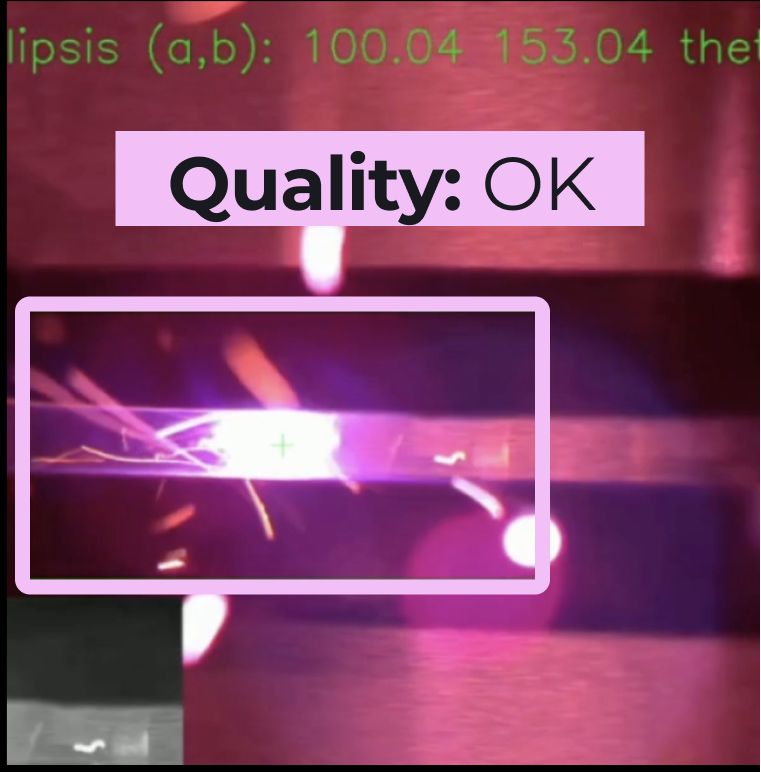

laser cutting, laser welding, additive process monitoring, quality inspection

Computer vision AI is critical in the realms of Industry 4.0, smart manufacturing, and the realization of the smart factory concept. Artificial intelligence (AI) powered by computer vision capabilities is at the heart of this technological revolution. Computer vision AI is the ability of machines to perceive and interpret visual information, replicating human-like vision through algorithms and deep learning models. Computer vision AI solutions can extract valuable insights from images and videos, identify objects, detect patterns, and make informed decisions by analyzing them. In the context of Industry 4.0, computer vision AI enables manufacturers to improve operational efficiency, quality control processes, predictive maintenance, and workforce safety measures. It enables machines to “see” and understand the production environment, allowing for real-time monitoring, automation, and optimization. With its transformative potential, computer vision AI is revolutionizing the manufacturing landscape, paving the way for advanced levels of productivity, accuracy, and adaptability.

Understanding Computer Vision AI

How computer vision AI works in manufacturing

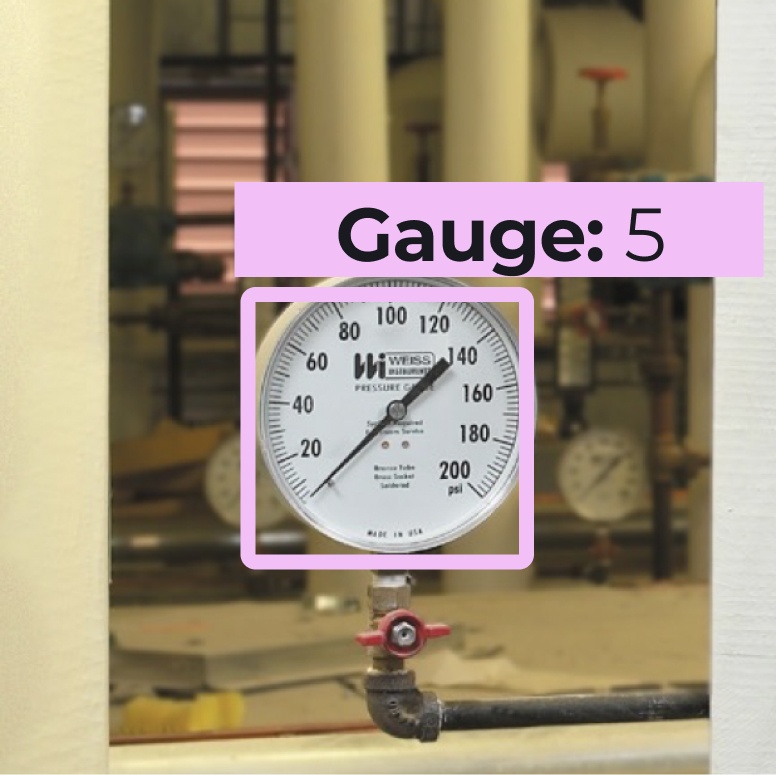

To enable machines to understand and interpret visual data in the manufacturing environment, computer vision AI employs a combination of hardware, software, and algorithms. The process begins with images or videos being captured using cameras or sensors strategically placed throughout the production line or facility. These visual inputs are then fed into computer vision AI systems, which perform several complex operations on them. The AI algorithms analyze visual data using deep learning models and neural networks to extract meaningful features and patterns. This analysis includes object recognition, image segmentation, motion tracking, and anomaly detection. Computer vision AI can identify defects, classify products, track objects, monitor processes, and make informed decisions by comparing captured data to predefined standards or trained models.

Watch our 30′ webinar and see in action how PerCV.ai Platform supports Industry 4.0 solutions that employ computer vision and AI at the edge, turning image and video data into KPIs that matter.

Benefits of computer vision AI in manufacturing processes

Computer vision AI provides numerous benefits for manufacturing processes, revolutionizing how products are manufactured. For starters, it vastly improves quality control and inspection. Computer vision AI systems can detect even the most subtle flaws by automating defect detection and classification, ensuring that only products that meet stringent quality standards are released. This increases customer satisfaction while decreasing the likelihood of costly recalls or returns. Furthermore, computer vision AI allows for real-time monitoring of production lines, alerting operators to any deviations or abnormalities and enabling immediate corrective actions.

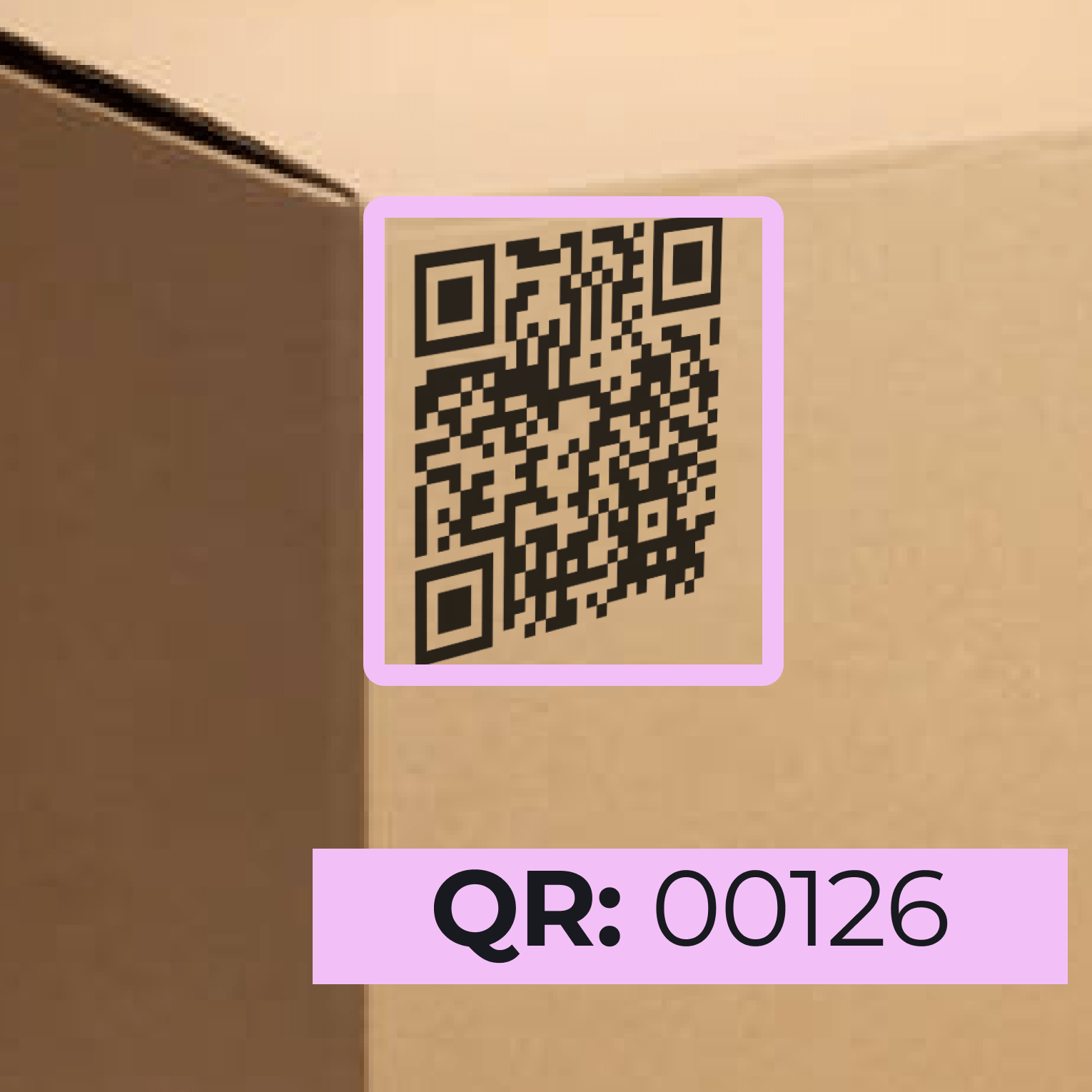

Second, artificial intelligence in computer vision improves productivity and efficiency. It optimizes inventory management by automating object recognition and tracking, preventing misplaced or missing components, and streamlining the supply chain. Furthermore, computer vision AI enables monitoring of complex processes which are comprised by a number of activities. In the example of the loading processes, the loading dock monitoring is combining number plate recognition (ANPR) for the involved vehicles (i.e. trucks), scanning of QR codes on products, ledger reading, and personnel tracking, to provide a holistic monitoring solution.

Finally, computer vision AI improves worker safety and monitoring. It can detect hazardous conditions, monitor personnel movement, and ensure safety protocols are followed. It creates a safer working environment and reduces the likelihood of accidents by alerting operators to potential risks or violations.

Key Applications of Computer Vision AI in Manufacturing

A. Quality Control and Inspection

Automated defect detection and classification

Automation of defect detection and classification is one of the primary applications of computer vision AI in manufacturing. AI systems for computer vision can analyze images or videos of products in real-time, comparing them to predefined standards or trained models. These systems can detect even the most minor defects, such as scratches, dents, or misalignments, by utilizing advanced algorithms. Additionally, computer vision AI can classify defects based on severity or type, providing valuable insights for process improvement and quality assurance. This automated approach not only improves quality control accuracy and efficiency but also reduces reliance on manual inspection, reducing human errors and ensuring consistent and reliable results.

Visual inspection of products for flaws or deviations

Computer vision AI enables visual inspection of products to identify flaws or deviations from desired specifications. By analyzing visual data, AI algorithms can detect irregularities in shape, color, texture, or size, ensuring that products meet the required standards. This includes inspecting components, assemblies, or finished goods for surface defects, product variations, or assembly errors. The ability to perform detailed and precise visual inspections in real-time enables manufacturers to identify potential issues early in the production process, minimizing waste and preventing the shipment of defective products to customers. By ensuring consistent product quality, computer vision AI enhances customer satisfaction, brand reputation, and overall competitiveness.

Real-time monitoring of production lines

Computer Vision AI is also critical in the real-time monitoring of production lines. AI systems can capture and analyze visual data in real time by integrating cameras or sensors throughout the manufacturing environment. This enables manufacturers to closely monitor the manufacturing process, detecting deviations or abnormalities that may impact product quality or operational efficiency. For example, computer vision AI can detect color or shape variations during component assembly, ensuring consistent product appearance. It can also monitor the positioning or alignment of objects on the assembly line, preventing errors or jams. Real-time monitoring enabled by computer vision AI enables manufacturers to take immediate corrective actions, reducing downtime, improving process efficiency, and reducing the likelihood of defective products reaching the market.

Next-gen Quality Control Automation based on AI & Computer Vision

Check out how our state-of-the-art system detects and classifies defects with unmatched accuracy, performs meticulous visual inspections to ensure flawless products, and provides real-time monitoring of production lines.

Functionalities

- Product Defect Detection (i.e., dents, spills, tears, deformations, scratches)

- Packaging Identification & Counting

- Real-time QA, QC, and production analytics

- Real-time triggering, i.e., rejection systems, alarms upon specific events

- Integration with pre-existing software (ERP, WMS) and industrial automation (PLC or deviation systems)

B. Object Recognition and Tracking

Object recognition and tracking is another vital application of computer vision AI that seamlessly complements manufacturing quality control and inspection processes. By leveraging advanced algorithms, computer vision AI systems can identify and track objects along the assembly line with exceptional accuracy and speed. This capability enables manufacturers to achieve several key benefits, including efficient inventory management, supply chain optimization, and prevention of misplaced or missing components.

Identification and tracking of objects on the assembly line

Computer vision AI is particularly good at identifying and tracking objects as they move down an assembly line. The system can precisely recognize and monitor the location and status of each component or product by analyzing visual data captured by cameras or sensors. This enables manufacturers to ensure that the correct objects are in the right place at the right time, reducing errors and increasing overall production efficiency.

Inventory management and supply chain optimization

Computer vision AI contributes to efficient inventory management and supply chain optimization through object recognition and tracking. Manufacturers can gain real-time insights into inventory levels, demand fluctuations, and production requirements by accurately monitoring the movement and flow of objects. This data allows for proactive decision-making, such as optimizing stock levels, improving order fulfillment, and shortening lead times. Manufacturers can save money, improve customer satisfaction, and grow their businesses by streamlining inventory management and supply chain processes.

Prevention of misplaced or missing components

Computer vision AI serves as a dependable safeguard against misplaced or missing components. The system can quickly identify any deviations or irregularities by continuously tracking objects throughout the production line. This proactive approach allows for prompt corrective actions, avoiding costly errors and ensuring that products are assembled with all necessary components. Manufacturers can maintain product quality, reduce waste, and improve operational efficiency by minimizing the risk of misplaced or missing parts.

C. Robotics and Automation

Building upon the foundation of object recognition and tracking, computer vision AI plays a pivotal role in robotics and automation within the manufacturing industry. By integrating computer vision AI with collaborative robots (cobots), manufacturers can unlock a range of benefits, including precise object manipulation and assembly, enhanced safety measures in human-robot collaboration, and improved overall productivity.

Which is the value added by Computer Vision AI to robots or cobots?

SUCCESS STORY

Computer Vision AI in Hybrid Processing Robotic Systems

Enhancing Precision and Efficiency

The integration of computer vision AI with robotics and automation extends to innovative robotic-based platforms, such as the Hybrid Processing Robotic system – HYBRIDR. This cutting-edge system combines additive manufacturing technology like Laser Metal Deposition (LMD) with subtractive processes like milling and grinding. With computer vision AI, this hybrid system can achieve even greater precision and efficiency in its operations.

Computer vision AI enables the robotic system to perceive and understand the workpiece, its geometry, and its condition in real-time. The AI algorithms analyze the visual data, allowing the system to adapt its processing parameters accordingly. For instance, computer vision AI can assess the surface quality of the workpiece, identify areas that require additional material deposition or milling, and guide the robot’s actions with exceptional accuracy.

By integrating computer vision AI with the Hybrid Processing Robotic system, manufacturers can achieve precise control over the additive and subtractive processes, optimizing material usage and reducing waste. The AI-powered system can automatically detect surface defects, deviations, or inconsistencies, allowing for immediate corrective actions. Moreover, it can ensure precise alignment between the additive and subtractive processes, resulting in a finished product that meets the highest quality standards.

The collaborative nature of the Hybrid Processing Robotic system, combined with the perceptual abilities of computer vision AI, brings together the advantages of both additive and subtractive technologies. This innovative solution offers manufacturers the flexibility to create complex components with high dimensional accuracy, intricate details, and improved surface finishes. Learn more about the system at http://hybridr-project.eu/

D. Workforce Safety and Monitoring

Another critical application emerges from the integration of computer vision AI with robotics and automation: workforce safety and monitoring. Manufacturers can detect hazardous conditions or situations, track personnel and equipment in real-time, and ensure compliance with safety protocols and regulations by leveraging computer vision AI.

Detection of hazardous conditions or situations

Computer vision AI systems equipped with advanced algorithms can identify hazardous conditions or situations within the manufacturing environment. By continuously analyzing visual data from cameras or sensors, the AI system can detect potential risks, such as spills, leaks, or equipment malfunctions. This early detection allows for prompt action, minimizing the likelihood of accidents or injuries. By prioritizing worker safety through the use of computer vision AI, manufacturers can create a secure working environment for their employees.

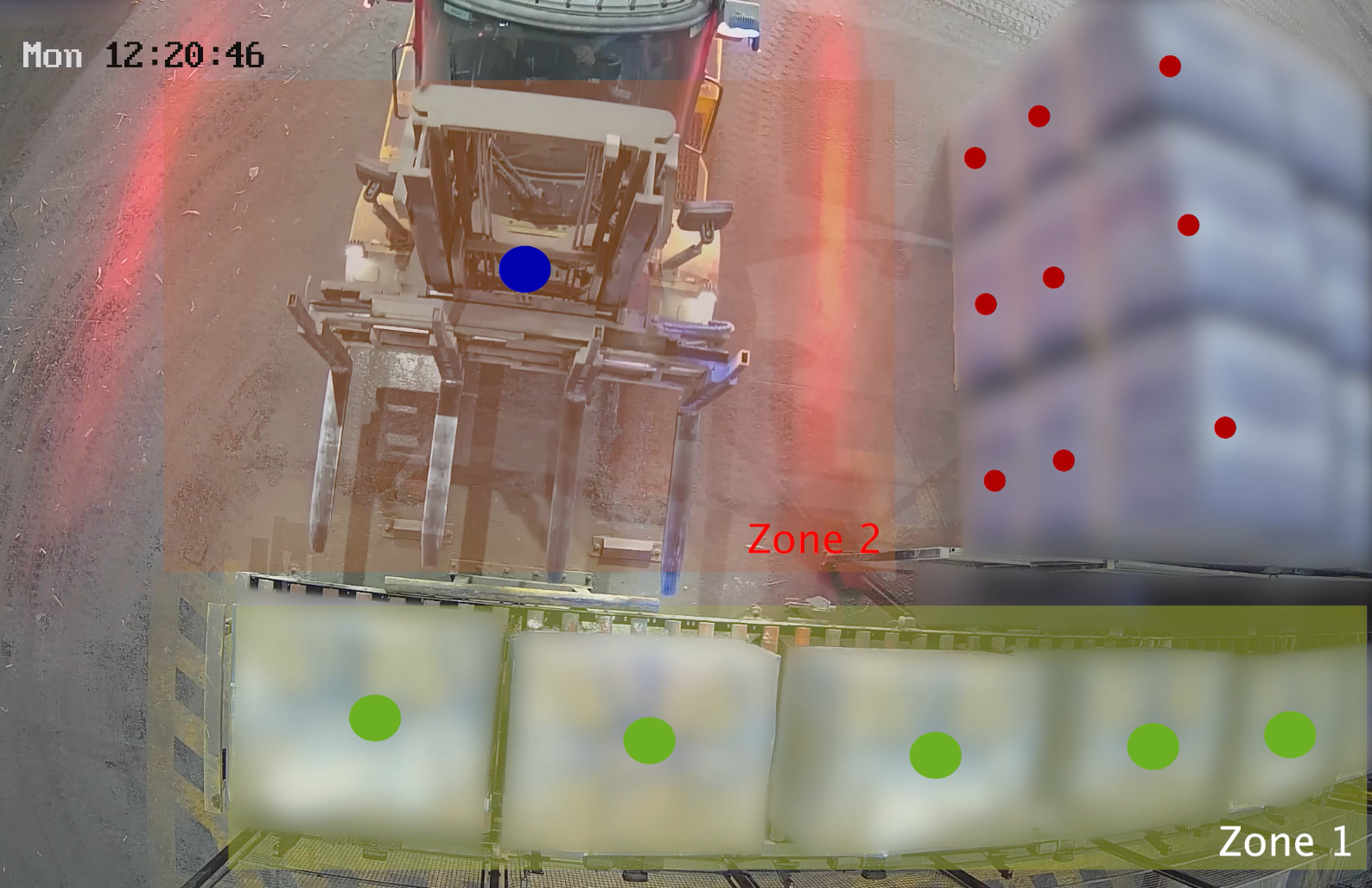

Real-time tracking of personnel and equipment

Computer Vision AI makes it also possible to track people and equipment in real time within the manufacturing facility. The AI system can precisely track worker movement and location by utilizing visual data, ensuring their safety and preventing unauthorized access to restricted areas. The system can also monitor machinery, such as forklifts or robots, to spot potential collisions or dangerous interactions. Real-time tracking improves situational awareness, allowing for quick reactions to avoid accidents and maximize productivity.

Ensuring compliance with safety protocols and regulations

Compliance with safety rules and regulations is essential, and Vision AI is a key component. The AI system can identify safety protocol violations such as improper use of personal protective equipment (PPE), unauthorized access to dangerous areas, or non-compliance with safety regulations by examining visual data. In order to enable prompt corrective action, the system can send real-time alerts to employees and supervisors. The risk of accidents, penalties, and legal liabilities is decreased thanks to this capability, which makes sure that safety procedures are followed.

How to Start with Computer Vision AI?

Corporations interested in adopting computer vision AI to their manufacturing process have two main options to consider. The first option involves obtaining an off-the-shelf or tailor-made solution, which is ideal for those with limited resources or knowledge of AI but require a quick and robust solution. The second option entails developing a custom Vision AI product or solution, suitable for organizations that possess a team of data scientists, AI engineers, or ML developers and seek greater flexibility and control over the development process. Both options offer pathways for individuals and businesses to embrace the power of computer vision AI according to their specific needs and capabilities.

Get an off-the-shelf or tailor-made solution

For those who have limited resources or knowledge of AI but need a quick and reliable solution, opting for an off-the-shelf or tailor-made end-to-end computer vision AI solution is a viable choice. This option is suitable for integrators or end customers who require a fast implementation without the need for extensive AI expertise. Off-the-shelf solutions offer pre-built models and software packages that can be readily deployed, while tailor-made solutions can be customized to specific requirements. These solutions typically come with user-friendly interfaces, documentation, and support, allowing users to benefit from computer vision AI without investing significant time and resources in development.

Develop your own Vision AI product or solution

For organizations that have a team of data scientists, AI engineers, or ML developers with the necessary expertise, developing their own Vision AI product or solution is a viable option. This approach allows for greater flexibility and customization to address specific business needs. By leveraging in-house expertise, organizations can design and train models tailored to their unique use cases. Developing a Vision AI solution in-house provides control over the entire development process, from data collection and annotation to model training and deployment. This option is suitable for organizations with the required resources and expertise to invest in the development and maintenance of a Vision AI product or solution.